Posted: 2/9/23

20 Questions With Wyatt Mellon

Behind the Design: SCX10 Pro

By Matt Higgins

The Axial Adventure SCX10 Pro was designed by Horizon Hobby product development engineer Wyatt Mellon. It's an impressive piece of machinery. That's for sure, but Wyatt isn’t just a talented designer who’s skilled with CAD, he’s also an experienced RC rock crawling competitor who’s won multiple national-level crawling events.

1. Let’s cover a little about you, Wyatt. How did you get started in RC?

My dad introduced me to the world of RC with his several planes and a nitro monster truck. I always liked anything with wheels, so the monster truck immediately caught my attention. That truck was then sold to buy us matching stadium trucks we used to race on our backyard track together. That started the beginning of my customizing and upgrading. But I had my eye on one special RC car I really wanted, the Axial AX10 Scorpion kit. My parents got me one for my next birthday and my dad and I went to town building it up with high clearance links, rear steer, and a split 6-cell NiMH battery pack. It didn’t stop there. I spent hours online watching videos and reading forums about it and customizing it even more with a Jeep body and metal sliders. Then the SCX10 TR Dingo got released and I knew a scale crawler was what I was after.

2. How long have you worked at Horizon Hobby and Axial Adventure and what are some of your other Axial projects?

I have worked at Horizon for about two and a half years now. Let’s see, other Axial projects I’ve been involved with include the Axial SCX6, UTB18, and AX24AX24.

3. Besides RC rock crawling, what are some of your interests?

My other main interests I have are going to the desert and dunes with my RZR, dirt bike, or quad; rock crawling in my Jeep; drifting cars; RC 1/10- and 1/8-scale buggy racing, and RC drifting.

4. Alright, let’s get into the new scale rig. How long did it take you to design the SCX10 Pro?

When I first started working at Axial, during one of the test sessions of the SCX6 before it was released, I brought along one of my personal crawlers I had designed and built. I had designed it to be an all-in-one trail and comp crawler featuring selectable underdrive, servo on axle, G-10 material chassis and a forward motor mount. Once some of the other guys saw it, the SCX10 Pro project came to life. I spent about six months designing and fine tuning this vehicle to have all of the same features and more, but now done slightly better since Axial has the assets of different manufacturing methods than I previously had access to.

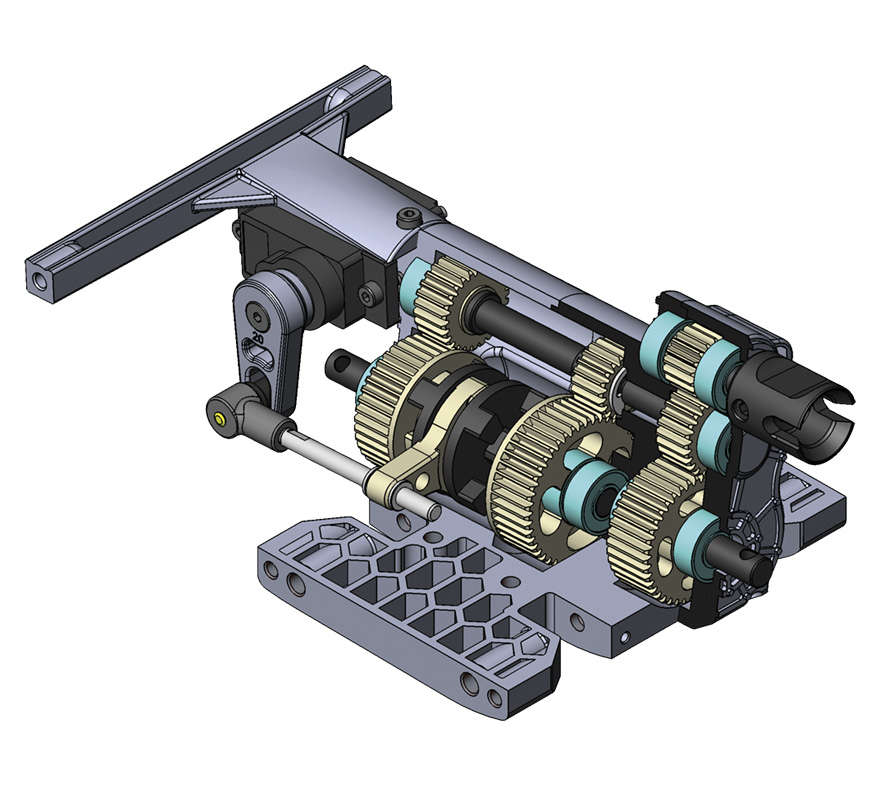

5. What component or aspect of the design did you start with and why?

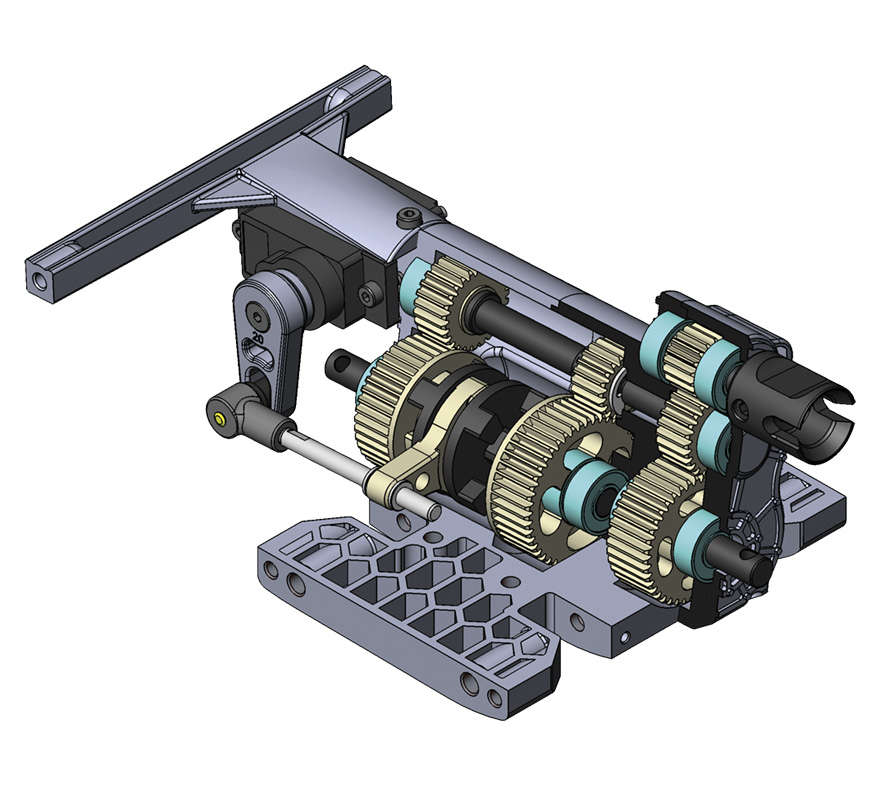

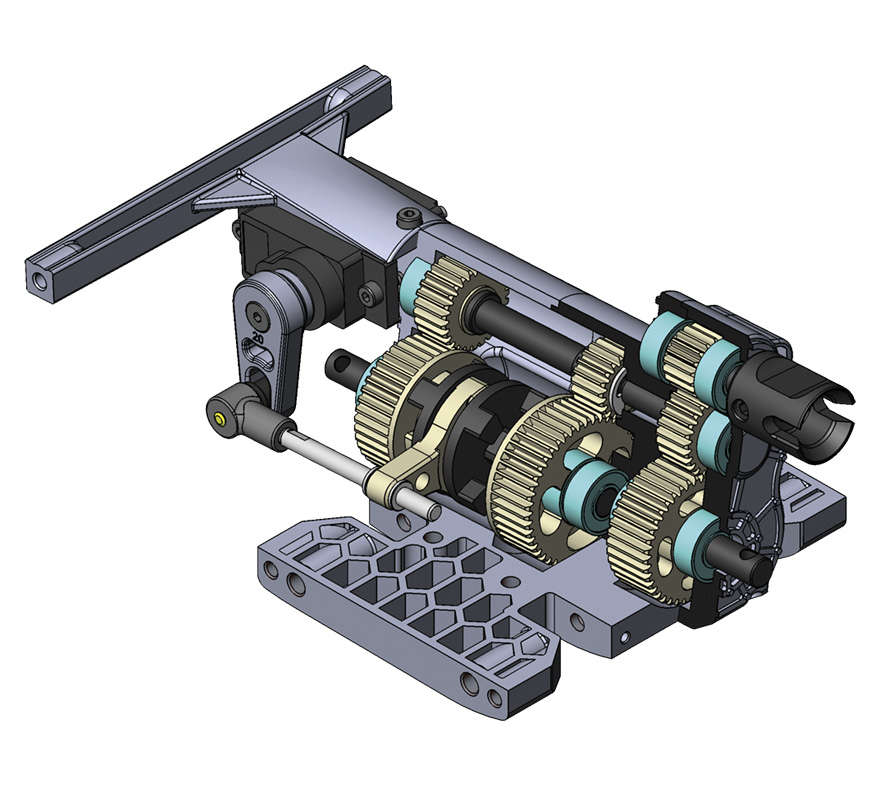

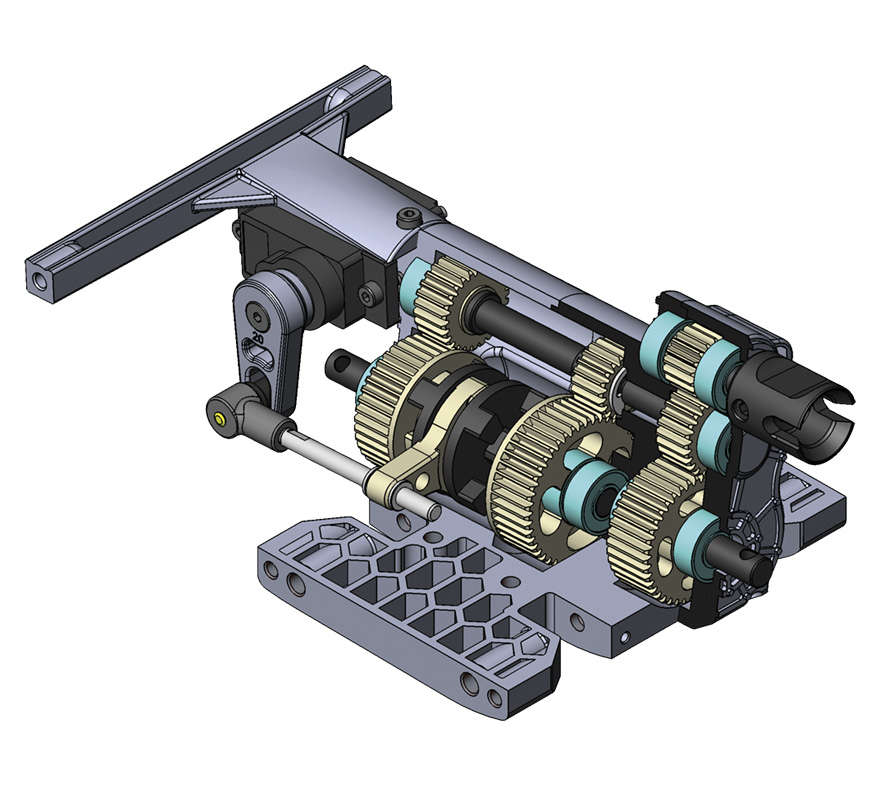

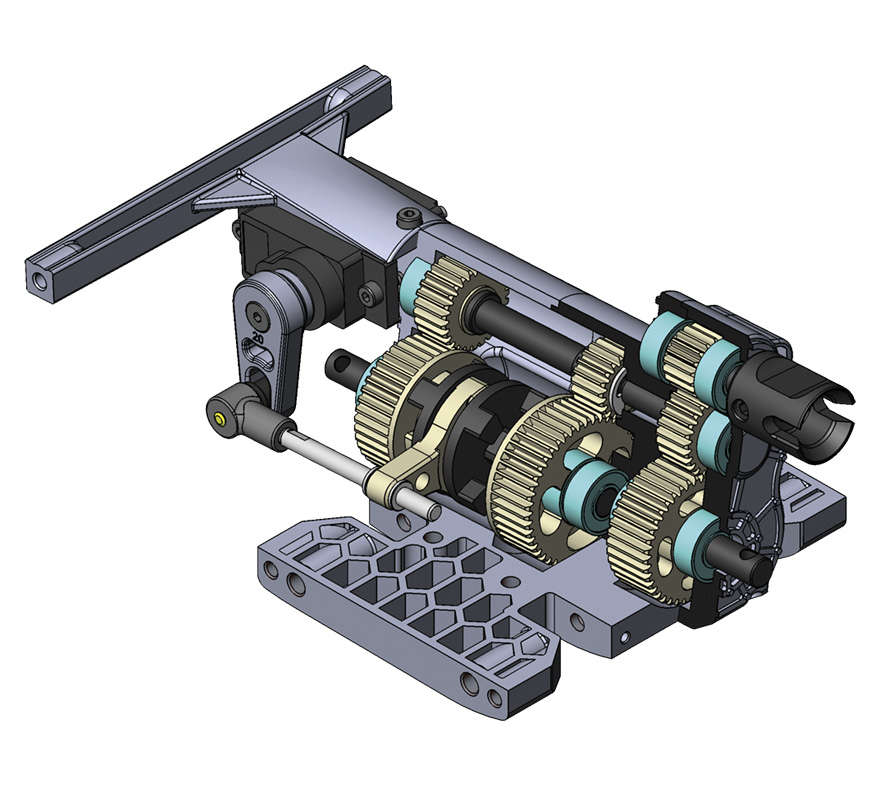

The main features I started with were the selectable underdrive transmission, motor mount, and the servo on axle. In order to get everything packaged where I wanted it in the chassis to get the ideal weight distribution and link geometry I needed to know where the servo and the motor were going to be.

6. What was the most difficult element to design on the SCX10 Pro?

I would say the most difficult element to include in the design was to make it user-friendly. I knew my truck was not the easiest to work on and it needed some tools everyone might not have on hand. So, I had to change some things around to make it easier to work on and add parts such as bumpers, sliders, and different bodies.

7. What feature or features are you most proud of?

I am most proud of the selectable underdrive transmission since I came up with it on my own and, to my knowledge, I was the first one to use it in competition. I’m also proud of the orientation of the servo on the axle and keeping the axle the same width as standard SCX10 axles.

8. What are some features or details on the SCX10 Pro that you think people may miss or overlook?

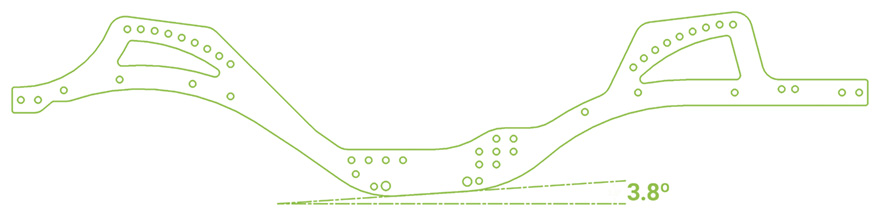

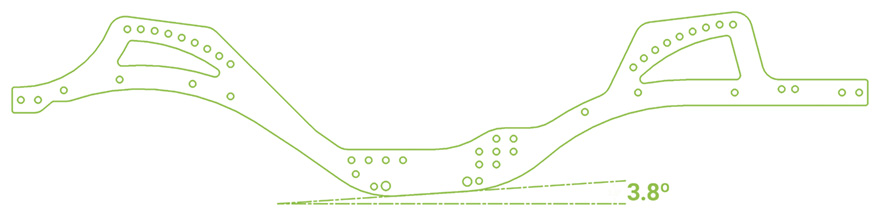

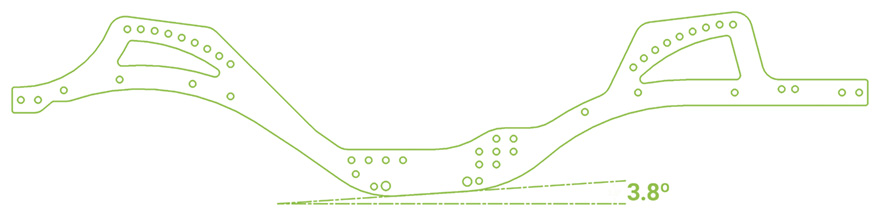

I think people may miss that the shock mounting locations on the chassis are on an arc centered to the axle center. When you stand up or laydown the shocks, it doesn’t change the ride height as much as other chassis do. Angling the shocks is for shock tuning, like you would tune shocks with oil and springs.

9. Could you describe when the underdrive selection would be useful? What would you look for, terrain or course features when previewing a course, that would make you select the underdrive vs. the one-to-one?

Having underdrive is useful for some climbs and having a tighter turning radius. I would usually find a feature that is a steep climb ramping up or a tight spot to turn around to get a better approach to select underdrive. Where you want your front tires to grip and drag the rear around to stretch the truck out and reach a ledge or stay more planted on an off camber drop off.

10. What servo do you recommend for the transmission?

I recommend the Spektrum SX108, it’s an updated version of a previous Spektrum servo. There are also other aftermarket servos that will fit and do the job.

11. The SCX10 Pro really isn’t just for comps. What are some of the features that make it perfect for anyone who just wants the most capable scale rig on the trial?

The main feature is the selectable underdrive which selects between 0% and 40%. On a trail run a lot of underdrive or overdrive can cause extra strain on the drivetrain and heat up electronics when it isn’t needed. This feature lets you drive on trail and decide when you want to use underdrive for that certain line you are pulling off to one up your buddies. Another feature is the option to run the servo on the axle or on the chassis. The chassis mounted servo still gives the scale appearance of a full size rig having a steering box and pitman arm. Also, included in the kit are different body posts to accommodate many different body options that are on the market today, whether it is a hard body or polycarbonate, it will mount up for a scale look. The bumper mounts also accept any Axial two-post bumper so there are already different bumpers out there depending on what look you are going for.

12. Any general kit building tips for the SCX10 Pro?

Do not tighten the spur gear too much, there's no spring to compress for a slipper clutch since there is no slipper clutch, it just has to be snug. Also, when purging the air bubbles out of the shocks, do it with the lower spring cup on, otherwise the piston is likely to extend out the top of the oil in the shock causing more air bubbles. Don’t overtighten the smaller screws on the skid plate, fine threads will strip out in the composite material.

13. What are some of the adjustments offered on the SCX10 Pro and how can people take advantage of them?

There are several upper link mounting positions for anti-squat and anti-dive depending on what you like the rig to feel like and what other parts you may put on it. There are also several shock mounting locations to fine tune ride height and how the springs and oil make the rig react. Take advantage of these adjustments, try changing them around while doing the same line, see what you like, everyone has a different driving style. Also, take advantage of the different servo winch mounting options if you are running one.

14. How about some general setup tips for shocks, tires, inserts, link mounting positions, etc.?

I usually like to run a lighter shock oil then most so that the rig reacts quicker to the terrain, instead of waiting for that tire to maybe settle back down it either settles down quicker or starts to roll which you can then react to, it is more predictable. The kit setup for link mounting positions are where I personally run them and my calculations have been done to get an all-around ideal geometry setup for straight axles and the 12.5” wheelbase. I always recommend a dual-stage foam to prevent tire sidewall roll and to support the truck on a steep climb or decent. Tires and compounds depend on the terrain, but I generally keep it consistent throughout all of my rigs.

15. What are some of the common setup mistakes you see competitors doing?

It’s the same mistake I have made many times before. All of the weight and components have to be as far forward as possible, but it’s not that simple. It matters how high those components sit on the chassis. It is often better to get the components lower and centered in the chassis rather than higher and more forward.

16. You’ve had a lot of success at some big rock crawling competitions. Any advice or strategies for people who might be taking the Pro to their first comp?

Don’t be discouraged by all of the rules and the time limit on course, and don’t be afraid to ask questions. Most people will be happy to help someone that’s new to comp crawling. The rules take time to learn. Have fun with it and learning will come naturally the more you attend.

17. How about some specific driving tips and tactics?

Just drive between the green things! But seriously just have fun with it. Of course there are nerves when running and a bunch of people are watching, but don’t get stressed out. When you look at a course, usually it’s the best to take the line you see and feel most comfortable with. Don’t watch too many people because you will second guess yourself. Once I figured that out, I started having more success.

18. There aren’t many engineers out there winning championships. Do you think this gives you an advantage when it comes time to design?

Definitely. I get test and tune and change designs based on high level real competition experience. Not to mention I get to spend weekends with some of the top drivers and builders in the world to get their instant feedback and suggestions.

19. What do you see in the future for RC rock crawling, both comps and scale crawling, in general?

I see the scale aspect sticking around. Everyone knows someone that enjoys model vehicles – now they are remote control models. Also, not everyone can afford a full-size Jeep or Toyota on 40-inch tires with lockers and coil over shocks, but you can own a scaled down version that’s just as much fun. Comps will never fully go away; competitiveness never dies. Even though the crawlers are scale in appearance, more performance than what is scale is wanted from them. I think RC rock crawling and RC in general will have more advancements as electronic technology improves.

20. Thank you, Wyatt. Anything in closing for people considering the Axial SCX10 Pro?

Whether you want another scale trail rig or a new comp rig, or maybe you want your first RC rock crawler kit, this one can do it all.

Follow @AxialAdventure on social media and be sure to post your #myAxialAdventure post! We can't wait to see where you go and what you do on your adventure!