Posted: 1/7/16

If you didn’t already know, tires make the single biggest difference in the overall performance of a competition vehicle. A fast motor will increase top speed, but if you want lower lap times, if you want to be in front of the competition, if you want to win, it is absolutely essential you spend time to getting the right tire setup on your Axial Racing vehicle. This includes tread pattern, rubber compound, size, inserts and even, to some extent, wheels.

While all Axial Racing vehicles include high-performance scale tires, there is no single best tire. What works perfectly at one rock racing track simply may not work at all at another track. Also, track conditions change, so what worked at one point in a race day might not be the ideal choice later in the same day.

Rock racing is tricky because what works exceptionally well on rocks is unlikely to work on high-speed dirt sections and vice versa. It is essentially impossible to pick out a rock racing tire without making some sort of compromise. The specific track you are racing on will determine which way you want to compromise performance.

Tread Pattern

The tread is the most obvious feature of a tire. All of the other features in a tire design matter to varying degrees, but it’s hard to argue that tread pattern makes a big difference.

Treads with taller, flexible lugs can sometimes be beneficial on rocks, but they are unlikely to do well on typical hard racing surfaces where the tread easily folds over. When the lug folds over, it provides inconsistent and unpredictable handling as they can slightly squirm around. If a track has a lot of silt, which is very common, tall lugs do help. Most racing-specific tires, however, have short lugs, so if the rock racing track you’re competing on has a lot of fast sections, select a tires with smaller, closer-spaced lugs.

Large voids (open spaces) between lugs help keep tires from clogging with soft, wet dirt. If the track is muddy due to weather conditions or heavy watering by the track crew, consider a tire with large spaces between the treads such as the Axial BFGoodrich Krawler T/A tire.

Another part of the tread to look at is the sidewall. Tires such as the Axial Maxxis Trepador and Axial Ripsaw have significant tread wrapping down the side of the tire carcass. These side treads can be a huge advantage on the rocky section and typically won’t impact handling on the fast sections.

Don’t be afraid to mix and match tires to achieve the desired handling. Often rock racers have a hard time with squirrelly handling on the fast sections and at the start. Going with a less aggressive front tire can help reduce oversteer. If the car slides (not spins out) in the corners, it will benefit a more aggressive front tire and might need more traction overall.

Rubber Compound

There are numerous rubber compounds to choose from. Softer compounds such as Axial’s R35 compound (white dot) are softer and stickier. Soft compounds provide more traction, but wear faster. A soft compound such as R35 is almost always better for rock racing.

In the same way treads can be mixed and matched, different compounds can be used the front compared to the rear. It might make sense to start with R35 compound with the rear tires only.

Size

Often, when selecting tires for rock crawling, the focus is on tire height, but width is just as important when choosing a rock racing tire. In general, and with all things being equal, a wider tire has an increased contact patch and will provide more traction. Narrow tires up front teamed up with wider rear tires can be an ideal setup. This is especially worth trying if your truck is struggling to track well in the corners.

While width is important when looking for the right front to rear balance, height is still important. The main benefit of taller tires is increased ground clearance. Taller tires also have taller sidewalls since we only use a few wheel sizes in R/C. Taller sidewalls have no benefit on the fast sections, but tall sidewalls do allow for a more flexible tire that can wrap around rocks and aid in climbing.

Inserts

In full-size tires, compressed air supports the tire. There are a few exceptions, of course. In R/C, foam inserts replaces the air, and just like the air inside a full-size tire, the foam supports the tire. Firmer foam is like higher PSI and softer foam is like less PSI.

Foam can be divided into four groups: open-cell, closed cell, memory, and multi-stage.

Open-cell foam is the most common type of foam found in R/C. Not all open-cell foam is the same; there are countless varieties. This is the same for all of the foam types. Axial Racing includes a medium density (firmness) foam insert.

Closed-cell foam is molded foam and in the last five years has become the most common type of foam used with racing vehicles. A solid closed-cell insert is, however, almost always too firm to work well for rock racing.

Memory foam is often used in rock crawling, but it can have some ill effects when rock racing. Memory foam is heavier than both open- and closed-cell foam. This helps with rock crawling, but can actually cause accelerated parts wear. Unlike traditional foam, memory foam is slow to return to its original shape after encountering an obstacle. This characteristic of memory foam helps when rock crawling where going slow is the norm. The memory foam conforms to and wraps around obstacles. When rock racing, if memory foam is compressed it will cause an out-of-balance tires and erratic handling.

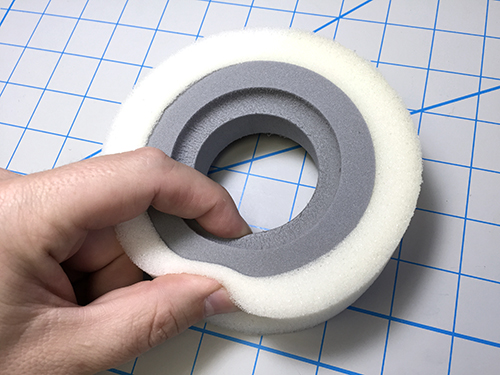

Multi-stage foams use more than one type of foam and allow you to have a “best of both worlds” setup. Just about any combination is possible, but the best setup for rock racing would be a closed-cell inner ring surrounded by an open-cell outer ring.

How the foam fits inside the tire also impacts how firm it feels. For rock racing, it is best to use a foam insert properly sized to the tire. An oversized foam insert will make the foam firmer than possibly desired and an undersized foam will provide erratic handling as it moves around inside the tire. In high-speed racing, a slight air gap (space between outside top of the foam and inside of the tread are) will increase traction without hampering handling as long air gap isn’t too large. Creating a consistent air gap when using open-cell foam can be difficult, but with careful attention to detail it is possible.

An important item to consider is that foam inserts wear out. Sometimes tires might not show a lot of visible wear, but the inserts inside have broken down. Open-cell foam wears out the fastest. Often simply squeezing a tire doesn’t demonstrate how the foam is holding up. Instead, squeeze all of the tires and make sure the foam rebounds at the same in rate in all of the tires. Carefully feel the tires to see if the is an increased gap between the tire and the foam insert. If you’re using bead lock wheels, disassembling the tires and wheels may be in order.

Wheels

Where rock crawlers often favor heavier aluminum wheels, lightweight wheels are best rock racing. Increasing rotational mass, such as with heavy wheels, is never desirable on a high-speed vehicle. In fact, lightweight and more flexible wheels will most likely improve handling over bumps and jumps.

While bead lock wheels have the advantages of being easily reused and unlikely to fail (have a tire come apart) if properly installed, they are heavier. Glue-up style one-piece wheels are often appropriately flexible and lightweight, which, as stated, are good qualities for racing.