Posted: 2/8/12

See Part 2 of the build HERE.See Part 1 of the build HERE.

Wanted to share the latest updates to my Formula Offroad build. When I first built this rig using AX10 axles the Wraith™ had just hit the market. At the time I thought it would be great to have those new AR60 axles found in the Wraith™ underneath my Formula Offroad rig. Well its been long enough, time to get it done!

But first, I will explain a few of the advantages of the AR60 axles for this application.

Axial R&D developed the new AR60 axles for a few reason's. First, we wanted the Wraith™ to perform well at higher speeds. Speed isn't all about straight line performance, stability is important as well. The AX10 axles with some wideners would not have cut it. To increase handling ability at speeds we needed to utilize a design with proper scrub radius. So what is Scrub radius and why is it so important for handling? Scrub Radius is determined by the kingpin location on the steering knuckles and hubs. Draw an imaginary line to the ground through the kingpin screws and ideally that imaginary line lands close to the center of the tire to achieve the ideal scrub radius.

Ideal, or zero scrub radius occurs when the kingpin line meets the ground at the center of the tire.

Here is a pic I found to help explain Scrub Radius (aka pivot angle radius):

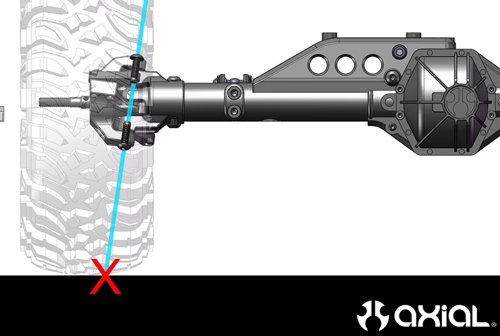

Now lets take a look at the AR60 axle by drawing a similar diagram.

The Blue line is the imaginary line I mentioned above. The screws this imaginary line travels through are the kingpin screws. The red "X" at the bottom of the tire is the location that the kingpin line meets the ground. You can see this very close to the center of the tire therefore the scrub radius is minimal.

On 1:1 cars you want this scrub radius to be as close to zero as possible. Vehicles with a large scrub radius require powerful steering systems to move the tire when steering. Cars with zero scrub radius can usually be driven without power steering. So this brings us to another important reason to reduce scrub radius. The larger the scrub radius the higher the torque required to steer it, therefore you need a stronger steering servo on your RC car. Keeping the scrub radius to a minimum will let your steering servo work at its full potential and use the steering torque efficiently.

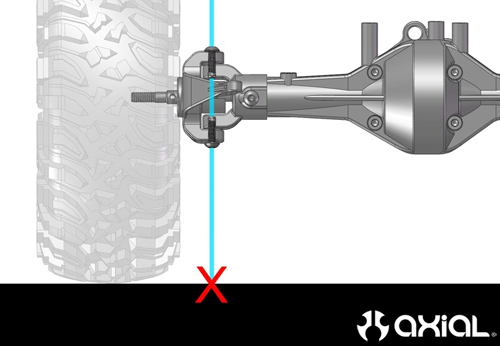

Lets look at my old setup using the AX10 axles and a wide offset wheel to achieve the width I wanted. Keep in mind that this is extreme due to the wheels I was using. Axial's current products that utilize the AX10 axle do not exhibit this large scrub radius.

Here you can see the distance from the center of the tire where it meets the ground is a good distance away from the red X. This creates a very large scrub radius.

There are few other important things to note when looking at the comparisons above. See how the imaginary line through the kingpin screws is at an incline on the AR60 axle? This is due to the inclined kingpin screws compared to the vertical kingpin screws on the AX10 axles. This inclined kingpin design was originally used on the XR10 competition Rock Crawler. It effectively moves the imaginary line closer to the center of the tire. The extra width of the AR60 axle and the incline kingpin angle both work together to increase handling, stability, and steering efficiency.

When Axial R&D started looking into Kingpin Inclination during the design of the XR10 competition Rock Crawler we found that the 1:1 automotive industry settled on an inclined kingpin angle of 7-9 degrees. Anything more and the contact patch of the tire is decreased during steering. The XR10 and AR60 axles utilize 8 degrees of kingpin inclination.

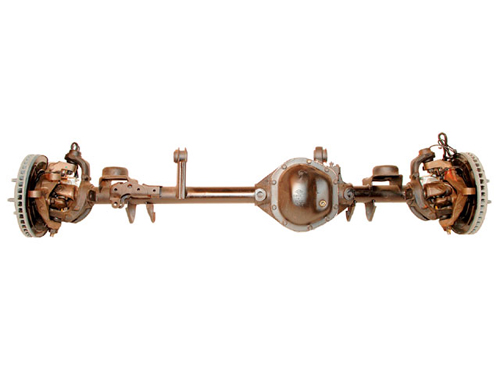

Another example of kingpin inclination can be seen on a Dana 44 Axle, its always cool to see real world 1:1 technology trickle down into the RC industry.

The second major design focus on the AR60 axles was strength. The Wraith™ was designed to handle more more speed and larger tires than any previous Axial product. The AR60 axle utilizes a 1 piece molded axle housing with thicker axle tubes. By removing the seam of the 2 piece axle housing and increasing the thickness the strength increase is substantial.

The third major design focus of the AR60 axle was adjustability. Some key adjustable features include:

- The AR60 axle can easily be flipped for a left or right offset pumpkin. The offset pumpkin allows for more clearance under a larger area of the axle and properly aligns the axle output with the transmission output to create a more efficient drivetrain.

- The lower link/shock mounts can be flipped to adjust height and anti-squat.

- Remove the diff cover and you can access the ring and pinion. Again this can also be flipped to keep the same rotation when you flip the axle housing to change the offset of the pumpkin.

- Caster angle can be changed in 18* increments to drastically change driving/handling characteristics.

- Upper 4 link truss is designed to be modular and act as a true truss to stiffen the axle housing.

Here is a exploded view showing the removal of the ring gear. Again Axial R&D took inspiration from 1:1 axles and the accessibility of the ring & pinion. It never gets old having to tear into an AR60 axle, its just too cool the way it comes apart and the diff cover gives you access to the axle internals.

Flipping the axles is also very easy. For this part of my Formula Offroad build I opted to install them flipped when compared to the Wraith. This was done to keep the transmission in the same orientation. If the AR60 axles did not have the capability to easily be flipped I would have been forced to rethink my whole build. The current transmission position allows me to run a full size 2 or 3S lipo pack under the hood. Once the axles were flipped all I had to do was flip the differentials inside the axle to correct the rotation. This extra adjustment is a great feature for changing the rotation to accommodate electronics or fighting torque twist.

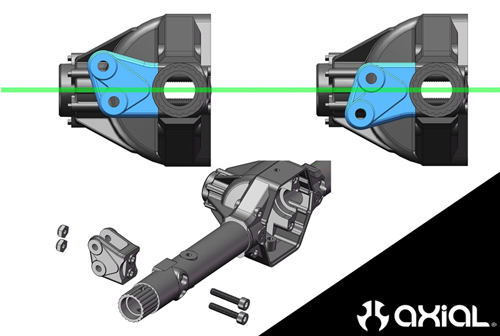

Along with flipping the axles, the lower link/shock mounts can be flipped to further fine tune the suspension. Anti-squat characteristics are determined by the location of the links at the chassis and the axle. Triangulation and link separation is key when setting up a 4 link suspension, the AR60 axles give you that extra adjustability needed with the lower link mounts. Take a look at the image below, the green line running through the center of the axle helps to show the difference when the link mounts are flipped (link mounts shown in blue). If you need to replace a lower link mount its an easy part to change out that does not require the entire AR60 axle housing to be replaced. Axial also sells a machined aluminum lower link mount AX30830.

Here are a few initial build pictures of the AR60 axles underneath my Formula Offroad rig. Because this is a custom build I did have to make some slight adjustments to bolt on the AR60 axles and still utilize the full stroke of the shocks without interfering. I will update this post with some more detailed photos soon.

I also opted to upgrade the driveshafts to the new AX30794 WB8 versions. The new WB8 driveshafts utilize a CV style joint that is rebuild-able.

The wheels are the new Axial 2.2/3.0 Narrow Raceline Renegade for the EXO Terra Buggy. Tires are Pro-Line SC Slingshots.

More build pics coming soon! Also need to get some electronics sorted out. Stay tuned, thanks for looking!

Not sure what Formula Offroad RC's are all about? Check out the RCCrawler.com Formula Offroad Forum HERE

Want to see a FOFF RC in action? Check out Bender's video HERE