Posted: 6/29/15

Axial Racing vehicles are patterned after full-size off-road vehicles, and at Axial, scale realism is more than skin deep. That means that Axial’s RC models are more than just realistic bodies on top of universal or generic platforms. The SCX10, for example, features solid axles and a linked suspension. The EXO Terra Buggy, on the other hand, has what is called independent suspension, front and rear. The Yeti has independent front suspension and a solid rear axle. In addition to axle types, there are different suspension types found on the same axle designs. Here are the basics of axle and suspension designs and what they are generally best for.

Solid Axle

The solid axle gets its name from the solid axle housing that goes from one side to the other, not the axle shafts inside. The internal axle shafts aren’t actually a single solid piece going all the way across. Inside the housing, there is an axle shaft on each side. This is true in the full-size world and with Axial axles. Axial’s design is extremely similar to a real solid axle. The AX10, SCX10 and Wraith all feature solid axles front and rear. The SCX10 features a narrower axle design; the Wraith platform and the current AX10 feature Axial’s wider AR60 axle that is the RC equivalent of a full floating 1-ton design.

Often the terms live axle and solid axle are used interchangeably. Most solid axles are live axles, but they aren’t the same thing. A live axle is any axle that is powered and not free rolling. When rock crawling, the solid axle is often the preferred design. In addition to the durability solid axles are known for, they also don’t lose ground clearance as a tire is pushed up during suspension articulation. The easiest way to visualize this to grab a pen or pencil and imagine it is a solid axle. Tilt one end up and over an obstacle and you can see how by driving tires up and over obstacles makes maintaining ground clearance easy. This exercise also makes it easy to see why it’s often best to place tires on rocks in the trail instead of trying to straddle them.

Independent Suspension

Independent suspension means the two opposing sides work independently from each other. If the right front tire hits a bump, the left front tire is not impacted. When speed is involved, the independent suspension is a better choice as it provides a much smoother ride. Keep in mind that when a tire on an independent setup encounters an obstacle, the tire and suspension components travel up, but the vehicle typically doesn’t. This allows the vehicle to go over rough terrain at a fast rate and remain stable. Picture all of the wheels moving up and down independently as a truck races across a desert terrain. The downside is when traversing rocks, the center section of the chassis will stay low to the ground as the tires move up and over rocks. Many full-size trucks have independent front suspensions (IFS) paired with a solid rear axle. This used to be common on only 2WD trucks, but is essentially the standard for the majority of factory trucks. There are many SUVs that have front and rear independent suspensions.

3-link

A solid axle can be attached to the frame or chassis of the vehicle in a number of ways. Probably the oldest and simplest way is via a leaf spring setup. Vehicles that are engineered for better ride quality and articulation (suspension movement) now use coil springs. Using coil springs, however, requires the axle to be held in proper position (and still articulate or move). This is done via links. There are a variety of link setups. A 3-link setup, as the name implies, uses three links to connect the axle to the chassis. Take the SCX10, for example, the front suspension setup has two bottom links and a single upper Y-shaped link. Since the upper Y-shaped link attaches to the axle at one spot, this is called a traditional three link setup. To add a degree of confusion, the name a suspension design gets isn’t always based on the total number of links. This is because some suspension designs, even in R/C, will have a pan hard bar (or track bar) that helps locate the axle under the vehicle and keeps the axle housing from moving from side to side. So, someone may say they have a 3-link setup with a pan hard bar. This is a total of four links. It’s worth noting that a link design that is properly triangulated will not need a pan hard bar.

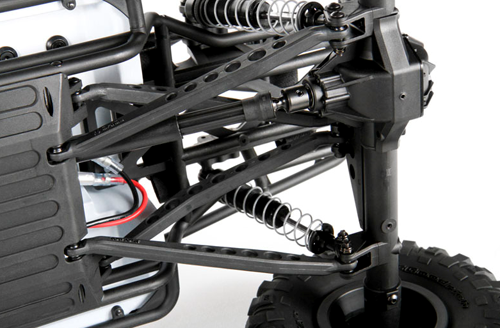

4-link

The Wraith uses a traditional triangulated 4-link suspension design. A close look reveals that at the axle the lower links are mounted far apart and then closer together at the chassis. The opposite is the case for the upper links, which have an even more pronounced triangulation. This design properly positions the axle, allows for plenty of articulation and is very strong. The previously mentioned Wraith has a 4-link setup front and rear. Depending of the particular version, you are most likely to find a 4-link rear suspension on the SCX10. The Yeti uses a 4-link rear suspension. And, the current AX10 platform, Ridgecrest and Deadbolt, use 4-links front and rear. The XR10 competition crawler also uses a 4-link design front and rear.

Example of an IFS and 4-Link vehicle: Yeti XL